Acme lead screws convert rotary motion into linear motion by turning either the screw or the nut. There are a number of reasons why acme lead screws are quickly becoming the norm for design engineers in linear motion applications involving everything from medical products to electronics.

helix linear - blog - acme screws

Precision Acme Screws Drive Medical Device Advancement

The medical field is one that's advancing at an unprecedented rate. One of the keys to this rapid advancement is the medical industry's increasing use of technology. One of the unheralded components doing the most to propel the medical industry forward is the precision acme screw.

An Acme Lead Screw to the Rescue

Do you require a flexible, yet simple and effective solution for a motion control application? Perhaps you need a solution that is reliable, long-lasting and requires little (or zero) maintenance? Chances are there's an acme lead screw for that.

Engineering Characteristics of a Precision Acme Screw

Do you have a mechanical design project in the works? If yes, you'll likely need to consider a linear motion control solution. While various lead screws are available for use in mechanical design, Acme screws have characteristics that separate them from competing hardware, like roller screws and ball screws. The engineering advantages of precision acme lead screws may be just what you need to add value to your design.

Acme Screws Drive Linear Motion Innovation

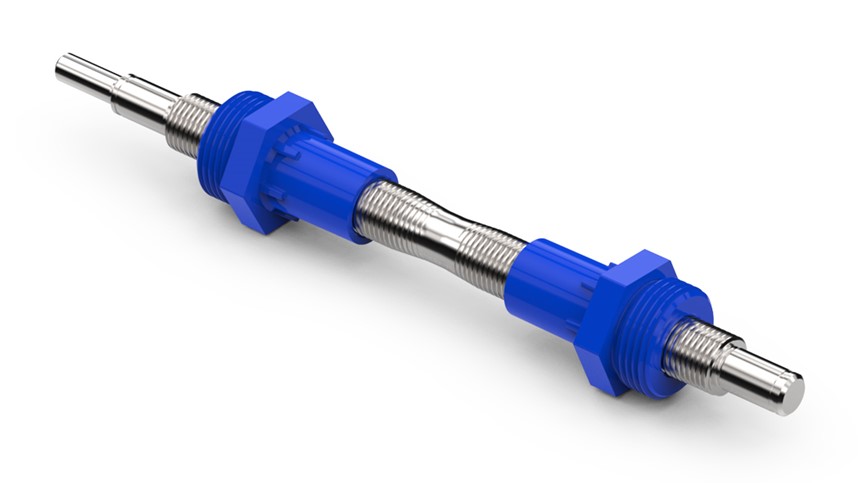

Acme lead screw assemblies are used to convert rotary motion into linear motion by turning the screw or the nut. One of the most popular types of lead screws uses the Acme thread form which typically has an included thread angle of 29°.

How to Choose a Lubricant for an Acme Screw

Ensuring optimal performance of acme screws and other types of lead screw assemblies often requires pairing the right screw and nut materials with the most suitable lubricant for a particular job

How to Evaluate Acme Screw Assembly Loads

Configuring an acme screw assembly that will not only perform but endure the demands of a linear motion application, requires a thorough understanding of the load requirements. Evaluating your loading conditions extends beyond the load that you want to move and the distance that you want to move it - it includes the effects of your application on the screw assembly itself.

How to Improve Acme Screw Efficiency

A staple for controlling linear motion for more than a century, the acme screw (a lead screw with a trapezoidal thread form angle of 29º) continues to be the best option for driving many of today’s motion control applications where efficiency is critical.

The Helix Acme Lead Screw Advantage

Acme screws provide distinct advantages for many of today’s linear motion applications, such as the motion control systems incorporated in many lead screw medical devices.

Choosing the Best Acme Screw for Your Application

Acme screws are a mainstay for supplying motion and positioning control in many types of machinery, including CNC milling machines, lathes, syringe pumps, linear actuators, 3D printers, and robotic systems.