The Efficient and Effective Criteria for Custom Made Acme Nuts

Acme Nut Customization

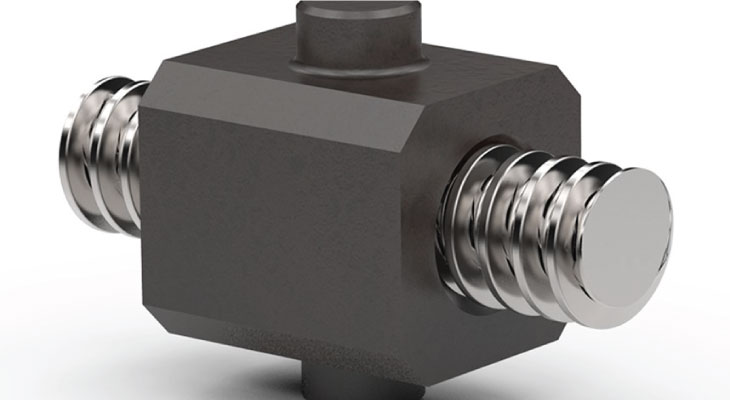

After you have selected the right lead screw for your application, it becomes a matter of choosing the best nut to meet the demands of your particular application.

Helix has a wide variety of standard acme nut designs, which offer many features and options to choose from. We can engineer and produce the perfect nut for your particular design requirements if you need something special. Customization may be simple dimensional changes, special material requirements, changing mounting hole patterns, or non-standard thread forms.

We mold and machine a wide array of lead nuts and actuator components from standard polymers such as PEEK, Torlon®, Acetal, Polypropylene, Turcite®, and custom engineered polymers that include PTFE, PFPE, silicone, carbon fibers, graphite, glass fibers, and molybdenum disulfide. Should cost or design constraints require a more integrated package, our engineering staff can help you simplify your design by combining several different components into a molded nut.

Design Considerations

* Some other things to consider when customizing an acme lead nut:

-

Temperature

-

Chemical Compatibility

-

End Machining

-

Wear Factor

-

Matching Leads

-

Maintenance

-

Acme Nut Lubrication

-

Backlash

-

Flange or No Flange

Custom Nut Outlook

It is predicted that a large portion of the lead screw market in the coming years will be from the demand for lab automation and medical treatment devices, where precise linear motion is crucial. These industry sectors have driven much of the custom nut and lead screw innovations.

Does your lead screw require a custom engineered lead nut? Be sure to consider the above bullet points, and feel free to contact one of our engineering experts if you need additional assistance.

Exceeding Expectations

For over 40 years, our expert engineers have been producing standard and customized lead screws and nuts that surpass industry expectations. To meet new market demands for innovative products and applications, our customers are looking to customize their acme nuts within their lead screw applications to boost productivity, efficiency, and precision for their end customers.