The Best Practices to Effectively Improve Acme Screw Efficiency!

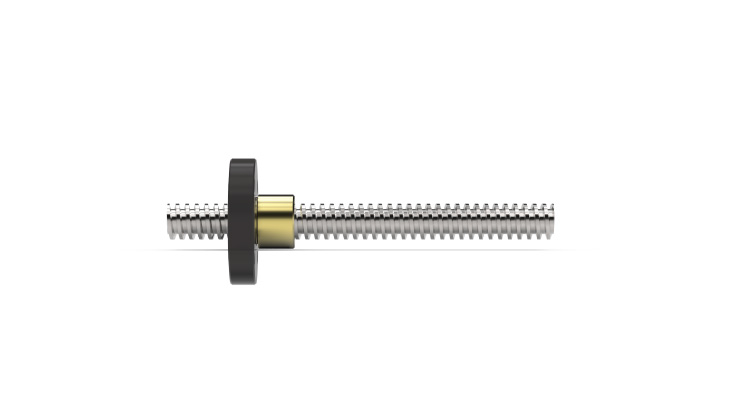

A staple for controlling linear motion for more than a century, the acme screw (a lead screw with a trapezoidal thread form angle of 29º) continues to be the best option for driving many of today’s motion control applications where efficiency is critical. That’s especially true when acme lead screws are configured for increased efficiency. But how does one improve screw efficiency, and how can they compete with ultra-efficient ball screws?

Why Consider Acme Screws

In the past, design engineers frequently perceived ball screws, which use re-circulating ball bearings, as the preferred choice for linear motion applications because of their higher levels of efficiency. However, the notion that ball screws are a better option than acme lead screws simply because ball screws are more efficient is misleading. By configuring a lead screw to your specific application, you can improve screw efficiency to match that of a ball screw while providing comparable load capacity, positioning accuracy, and other operational benefits.

Because acme lead screws offer many additional advantages - including flexibility in configuration and form factor; lubricant-free, clean, and quiet operation; and availability at a fraction of the cost of ball screws. Acme lead screws are simply a better choice for many of today’s linear motion control applications, such as the motion control systems incorporated in many medical devices.

What Determines Acme Screw Efficiency

The efficiency of an Acme lead screw refers to how well it converts rotary energy into linear energy or motion. Rolling contact has a lower coefficient of friction than sliding contact. Lead screws, including acme screws, offer efficiency levels of between 20 percent and 80 percent. There are several ways that you can improve acme lead screw efficiency, beginning with the thread angle.

An acme lead screw and most lead screws employ a trapezoidal thread form. The efficiency of a lead screw is highly dependent upon the helix angle of the screw thread. You can improve lead screw efficiency by increasing the helix angle of the lead screw thread. Higher helix angles are more efficient because less of the energy used to drive the lead screw is utilized to overcome friction. The number of times the screw must rotate to achieve the same linear displacement with a higher helix angle is reduced.

Acme Screw Nut Selection

Another way to improve screw efficiency involves the materials selected for the screw and the nut. Because lead screw performance relates to the coefficient of friction between the nut and the screw, the material used for the nut and screw can influence performance. In other words, nut material selection—self-lubricating plastics, polymers, or metals such as brass or bearing-grade bronze—will affect efficiency. Polymer nuts are generally more efficient.

Lubrication/PTFE Coating

Finally, the lubrication qualities of your lead screw and nut will have an impact on screw efficiency. Performance relies on a sufficient lubrication supply to the nut and screw interface, and proper lubrication is vital. Lubrication can be achieved through specially engineered polymer and plastic nuts and dry PTFE coatings, as well as through the use of silicone lubricants and PTFE additives.

Why Are Acme Screws So Efficient?

Acme lead screws are a desirable piece of machinery. What makes them so great? Some of the reasons are no braking system required, anti-backlash, low maintenance, and cost-effectiveness.

So, what is the PowerAc™ Acme Screw Efficiency?

The efficiency of PowerAc™ Acme Screw assemblies ranges from 15% to 85%. These efficiencies are dependent upon nut material, lubrication, lead, and thread form.

Backdriving

Normally, acme screws are used to convert rotary motion into linear motion. Backdriving is the result of the load pushing axially on the screw or nut to create rotary motion.

Generally, a nut with efficiency greater than 50% will have a tendency to backdrive. If a self-locking assembly is required, select a nut with an efficiency below 35%.

A Word of Caution

Vibration can cause any acme screw assembly to creep or backdrive. When using lead screws, the application should be analyzed to determine the necessity of a brake, especially when the possibility of injury may occur.

Helix Linear Technologies Can Help You Improve Acme Screw Efficiency

Why absorb the expense and operating disadvantages of using ball screws for your linear motion application when a specially configured acme lead screw from Helix Linear Technologies provides a better solution? Helix Linear has the engineering expertise and advanced manufacturing technologies to provide affordable, effective, and optimized solutions to meet your linear motion control needs.