Ten of the Main Reasons Lead Screws are Better Than Ball Screws!

Once only suitable for limited use in less demanding applications, lead screws (sometimes called power screws, acme screws, or translation screws) have evolved and now offer many significant advantages over alternative technologies like ball screws. Many of the lead and acme screws available today are considered the go-to choice for many specific motion control functions.

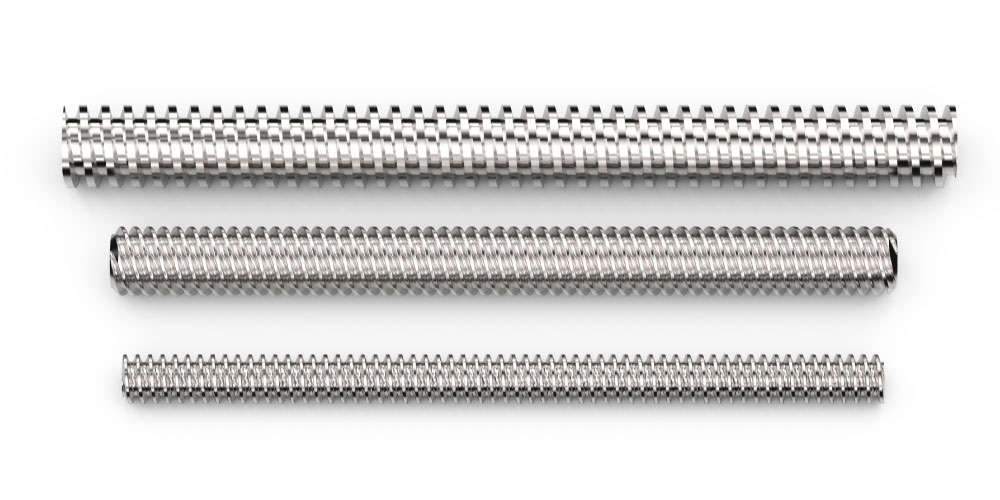

Unlike ball screws that function via the use of ball bearings, these lead screws have no internal moving parts. They rely on sliding friction between the nut and screw and feature deeper helical recesses with an acme or triangular thread and a mating nut to translate motion. As a result, these screws are generally less expensive and offer more flexibility than ball screws which are typically harder to modify or customize to specific applications. This advantage is just the tip of a growing lead screw iceberg of benefits, however.

Ten Reasons to Use Lead Screws in Your Next Linear Motion Application

1. Cost-Effectiveness

We already established that these screws are easier on the budget than ball screws, but that understates the relevant facts a bit. Because they can be easily tailored to meet a given application's specific performance requirements, they can essentially be "right-sized" – they cost anywhere from 25 to 85 percent less than ball screws. Thus, the cost is a significant differentiator between the technologies. This often requires a more excellent investment in life cycle testing in the design phase. Still, the long-term cost savings (which can be passed along to your customer) make the product more competitive in a fiscally constrained market.

2. Customization

Precision lead or acme screws offer increased customization options in lead sizes and diameters. For example, hundreds of options are available that make it possible for you to modify the screw to precisely accommodate your design, rather than having to make your design fit the envelope of the screw, which is often the case with ball screws.

3. Custom Nut Designs

Lead screws provide engineers with enhanced nut design flexibility. Should cost or design constraints require a more integrated package, custom nut designs can be designed to combine several components into a single molded nut. Lead nuts can be fabricated from various materials that are rated for different life cycle requirements. Lead nut materials can meet specific environmental conditions, including operating pressure-velocity and temperature, and can be molded or machined in complex shapes and sizes.

4. No Additional Lubrication

Unlike ball nuts, plastic lead nuts will operate without additional external lubrication thanks to the use of materials that help to reduce friction (less than 0.10).

5. Better Operation

Because there are no moving parts, lead or acme screws are quieter and less likely to cause vibration, leading to increased wear and tear on the assembly, leading to increased maintenance requirements and downtime. This helps make the newest breed of Helix screws especially well suited to precision applications such as medical equipment.

6. Vertical Appeal

Lead screws are designed to be self-locking at low leads, particularly useful in vertical applications.

7. Environmentally Friendly

Lead screws are less likely to suffer from particulate contamination, and they can incorporate a "dry" PTFE lubricant.

8. Energy Efficient

Many screw designs can be operated without the use of electric brakes helping to reduce the consumption of power. All ball screws will back-drive and require a brake to secure the load to ensure that the system operates safely and accurately.

9. Low Maintenance Requirements

Lead screws are ideal for applications where maintenance will be difficult or impossible. They also offer increased reliability over long service life and can be manufactured from materials that are resistant to corrosion.

10. Anti-backlash Technology

Precision is a critical requirement in most linear motion applications, and backlash (the gaps and spaces found in the helices of many nut and screw combinations) can make achieving that precision challenging. Lead screw assemblies can be designed to minimize this issue with various anti-backlash technologies. Anti-backlash screw assemblies deliver the accurate and repeatable linear motion that rivals ball screws.

There are times when a ball screw is an appropriate choice. Consult with a Helix Linear Technologies application engineer to discuss which option is an appropriate fit for your project needs.