Four Important Things You Should Know About Buying a Lead Screw

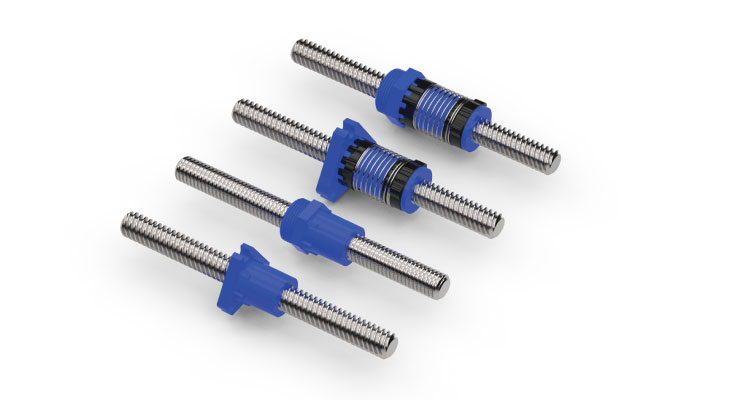

Lead screws are an excellent linear motion product that converts rotary motion to linear motion very economically and offered only moderate accuracy and repeatability until recently. Today's top manufacturers produce standard lead screws with .003"/inch lead accuracy and even better on request. These companies also make wide ranges of sizes, leading to choosing from and readily producing custom sizes and shapes of nuts to fit these screws. Here are four things that every engineer should keep in mind when selecting any lead screw.

1. Use PTFE coatings when possible: It's cheap and very effective in extending the life of your lead screw assembly. The nut is always the first thing to fail, and adding a PTFE coating to a lead screw will extend the life of the nut by a factor of 8-10X. Some manufacturers use water-based PTFE coatings that can wear over time and cause contamination, so be sure to request solvent-based coatings that do not outgas or wear. Most good PTFE coatings should last 25 million to 80 million inches of travel without wear, even in aggressive applications.

2. Ask for custom nuts: Unlike ball screws and ball nuts, it's straightforward to machine the different plastics that lead screw nuts are manufactured from, so try to incorporate as many other various parts connected to the nut into its design. Nuts are typically machined out of bar stock or plastic sheets or blocks.

3. End Machining / Straightening: The materials used to manufacture lead screws lend themselves to easy machining and can be done on any conventional lathe, mill, or OD grinding machine. This is easy if you are machining one or two pieces for prototypes and can, in most cases, be quicker than waiting on the manufacturer. However, if you are ordering several screws and the machining needs to be very accurate, it's best to let the manufacturer do the work fr you since it's something they do every day. The manufacturers will typically include the straightening processes in the machining cost if you have them do the machining for you.

4. Flats: Mounting a lead screw into your machine or device and adding bearings, lock nuts, encoders, and mating parts can get a little tricky when you need to hold onto the screw without damaging the threads or the machined ends. Adding a couple of flats on the outside diameter of the screw in the threaded section will go a long way toward helping you install a lead screw without damaging any of its critical dimensions. The flats will allow Flats to be machined onto the screw to enable the nut to travel over them, so you don't lose any travel by adding them.

Here are a couple of other things to keep in mind as well.

- Keep the lead screw clean and free of dust and metal chips

- Consider waiting until the last step to lubricate the screw with grease to minimize things getting messy

- Always keep the screw straight when installing it into bearing supports or mounting flanges

- If you need to hold the lead screw to keep it from rotating while you assemble a lock nut to it or screw it into a mounting flange, be sure not to dent or damage the threads. You can grab the screw with a pair of pliers if you put padding around the screw first. Rubber plastic sheeting works well.

- Consider adding wrench flats to the design of your lead screw. When designed correctly, the flats will still allow a nut to travel over them and will serve as a great way to keep the screw from rotating while you assemble your machine.

Contact us if you need help adding the wrench flats to your next lead screw design.