How to Select the Right Lead Screw for Your Linear Motion Application!

Linear motion, by its very definition, is movement along a line or linear path. Linear motion solutions take advantage of this movement to accomplish many tasks. However, selecting the right screw is not always easy, albeit necessary, to get the job done effectively and efficiently. The correct screw is essential, and, In many cases, lead screws are the right choice for the job. However, there are as many different screws as there are applications that employ them. Choosing the right one for your project can help you achieve more than you ever thought was possible. Before designing your next solution, remember to look at each of the following aspects of the application before choosing the right screw for your linear motion needs.

Important Factors to Consider in Linear Motion Projects

Thrust

Thrust is the amount of push that must be given to the screw to move it and its load. There are two types of thrust—peak and continuous. Peak thrust is a short burst during acceleration while continuous thrust occurs during the full linear motion application. The greater the thrust requirements are for a given application, the larger the diameter of the screw must be to meet those requirements.

Speed

How fast will the linear motion occur in your application? All lead screws have a critical velocity. This is a speed at which they will no longer perform at their best due to vibrations within the motion. There is a ratio that directly shows the velocity of the screw based on input RPM (rotations per minute.) A larger screw reduces the RPM in high-speed applications, so the more significant the screw you use, the lower the potential RPM.

Accuracy

Accuracy measures moving the load to the location while retaining a tolerance level. If you must maintain high accuracy, a highly accurate lead screw is essential. Screws with a higher accuracy level are generally the more expensive, but accuracy is critical for specific applications' success.

Repeatability

While many confuse repeatability with accuracy, these are different considerations. Repeatability measures how well the screw moves the load to the same position - time after time. This is more important than accuracy in many applications, and some of our Helix lead and acme screw assemblies are better suited to meet this need than others.

Backlash

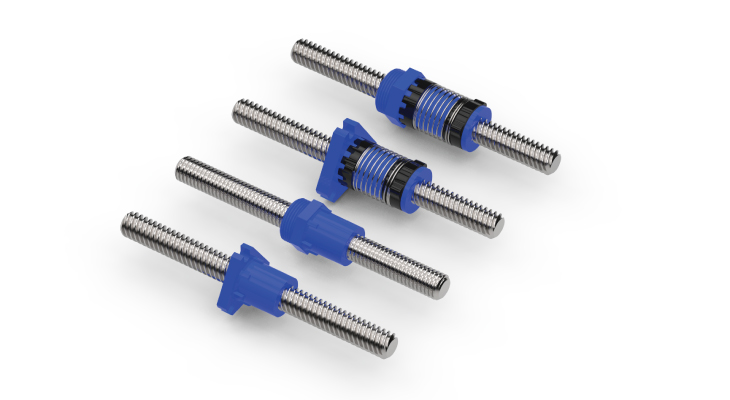

The amount of linear movement put in place between the screw and the nut without actually turning either is referred to as backlash. In specific applications, too much backlash can lead to problems. The new Helix AAB Axial Anti-Backlash screw assemblies are highly effective at reducing the amount of backlash within the system. Reducing backlash lowers the wear on all pieces and can improve the overall accuracy as well.

Resolution

Resolution is typically thought of as something controlled by the motor and controller of the linear tool. However, choosing the correct lead screw can also affect this to a small degree. A smaller diameter screw may require a less-powerful motor to achieve the exact resolution as a larger diameter screw.