How Lead Screws Effectively Drive Missile Fin Actuation Systems!

Lead and acme screws are used for various linear motion control applications, ranging from syringe pumps to pan-and-tilt systems for security cameras. However, one of the more exciting applications of these screws involves their use for driving the fin actuation that guides a missile to its target.

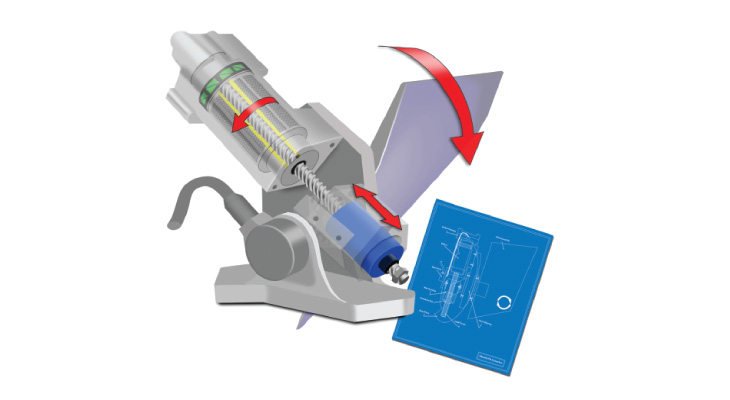

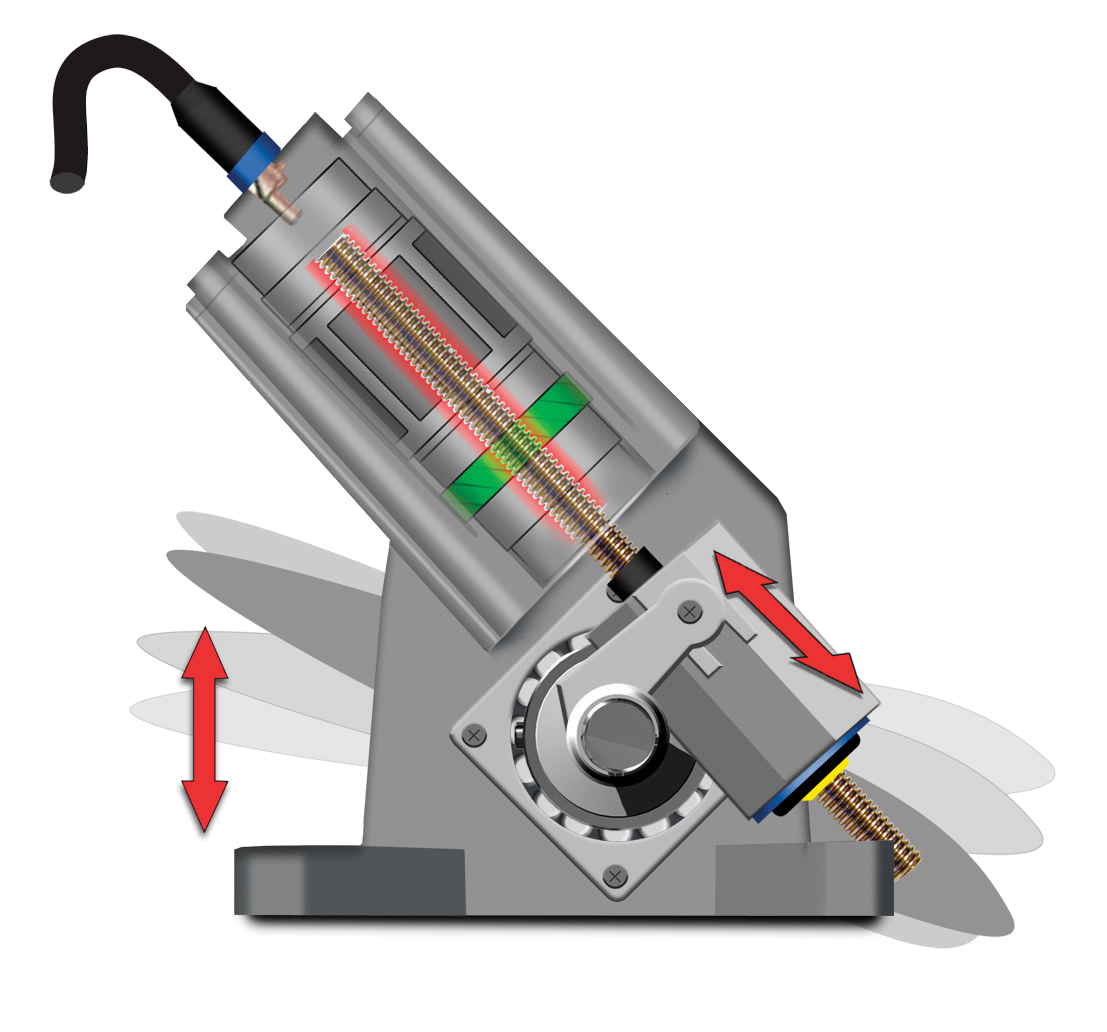

In this application, precision miniature screws are used to position the sighting mechanism that identifies and acquires the target while maneuvering at high speeds. The miniature screws also provide the actuation that controls the missile fins, guiding the missile’s flight. The fins are the missile’s wings. Some missiles also have actual wings. Using these screws to position wings and fins enables fine positioning and control to maximize speed and minimize drag during transonic and supersonic flight. In addition to directing the missile, screws are used to raise missile-launching systems and deploy sighting, range-finding, and antenna equipment.

How Precision Screws Function in Missile Fins

Precision-engineered miniature screws replace the hydraulic and pneumatic actuators formerly used for this purpose. Each screw assembly converts torque to thrust as the screw or nut turns to move the other component in a linear direction. Because the screw mechanism eliminates sliding friction and stick-slip, it requires little or no maintenance besides initial lubrication.

These screws automatically minimize the power required to drive missile-fin actuation because of their high efficiency. The size and weight of the fin drive transmission are also reduced, making miniature screws a better option for small missiles and targeted munitions.

Advantages of Miniature Screws for Missile Fin Actuation

Precision-engineered miniature lead and acme screws, like those produced by Helix Linear Technologies, provide many advantages when used for missile fin actuation over traditional linear motion control systems.

Key advantages of using Helix miniature lead screws for this application include:

- Lower cost – Helix screws cost less when compared to ball screw assemblies and pneumatic- or hydraulic-driven actuators.

- Custom designs – Screws can be custom-designed to match specific design envelopes.

- Range of Leads and Diameters – Screws are available in a range of leads and diameters from 1/8” to4”.

- Corrosion Protection – Stainless steel screws and internally lubricated Acetal nuts eliminate corrosion.

- Lubrication-free – Internally lubricated plastic nuts operate without lubrication.

- Quiet operation – Much less audible noise compared to ball screws.

- Lightweight and Compact – Highly efficient, miniature, lightweight assemblies mean less mass to move and less space consumed.

- Precision and Accuracy – Precision-engineered screws are highly accurate, with a lead accuracy of 70 millionths of an inch when used for missile fin guidance control mechanisms.

- Strong and Durable – High-strength steel provides proven reliability under rigorous and demanding environmental conditions and speeds.

- Better Field Performance – Helix screws feature a unique thread that maintains tighter and more rigid contact angle control, resulting in lower contact stresses, higher load capacity, reduced wear, optimum thrust control, and maximum predictable life.

- Precise Positioning – Tighter contact angle control over the entire stroke length maintains high repeatability with precise positioning.

- Long Life –Lead screws have less drag torque and provide longer life expectancy.

- Precision Engineering and Advanced Manufacturing – Helix can engineer customized and unique screw assemblies, machine screws to exact specifications and provide stock bearing mounts, motor mounts, or complete stage assemblies.

Use Helix Precision Screws to Support Your Most Sophisticated Applications

When you need to support a sophisticated linear motion control application like driving a missile fin actuation system, Helix Linear Technologies can provide you with advanced, precision-engineered lead screws to do the job. Helix offers a wide array of standard plastic nut assemblies in anti-backlash or traditional nut designs. Helix zero-backlash nut designs offer assemblies with high axial stiffness, zero backlashes, and the absolute minimum drag torque.

This case study includes more information about how lead screws drive missile fin actuation systems and more detailed application cut-aways.