Cart

Assembling lead screws into your machine or device can get tricky if you dont have the right tools and a screw design that helps make things easy.

So your new lead screws arrived and you're ready to install them into your machine. What's next? Well, here are a few things to keep in mind.

- Keep the lead screw clean and free of dust and metal chips

- Consider waiting until the last step to lubricate the screw with grease to minimize things getting messy

- Always keep the screw straight when installing it into bearing supports or mounting flanges

- If you need to hold the lead screw to keep it from rotating while you assemble a lock nut to it or screw it into a mounting flange, be sure not to dent or damage the threads. You can grab the screw with a pair of pliers if you put padding around the screw first. Rubber plastic sheeting works well.

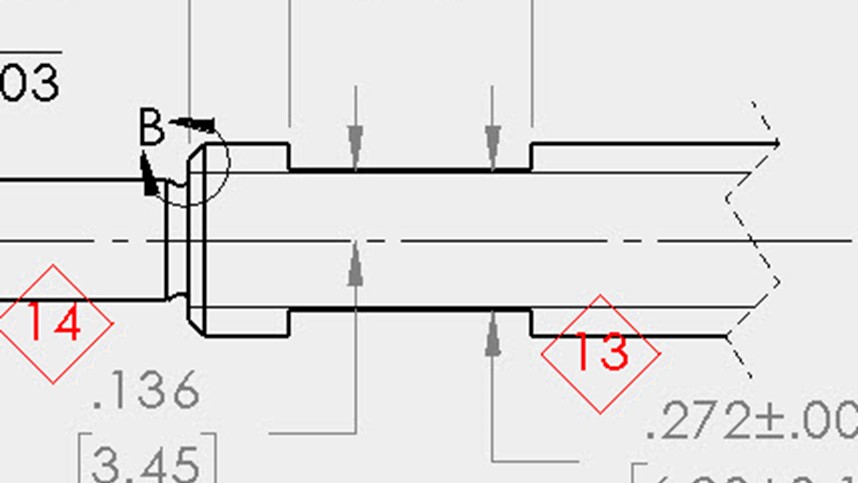

- Consider adding wrench flats to the design of your lead screw. When designed correctly, the flats will still allow a nut to travel over them and will serve as a a great way to keep the screw from rotating while you assemble your machine.

Contact us if you need help adding the wrench flats to your next lead screw design.