Helix Can-Stack Stepper Motor Linear Actuators

Can-stack stepper motor linear actuators offer an economical linear motion solution in a small package.

Benefits and features of can-stack linear actuators include:- Linear Step Accuracy ranges from 3 – to 400 microns.

- Dual ball bearings for greater precision and life.

- Permanent magnet linear motors convert rotary motion into linear motion.

- Linear actuator travel per step ranges from .05mm to .0254mm.

- Sizes ranging from 25 mm and 35 mm.

- Lead screw motors are also available from 6 mm to 15 mm.

- Reduced noise

- Increased torque density

Can-stack linear actuators are based on can-stack stepper motors which is a form of magnet steppers that have two stators stacked on top of each other. However, in order to make a linear actuator out of a can-stack stepper motor, the rotor is threaded, and normally a lead screw is put inside the rotor so it extends and retracts while the motor turns.

Applications That Use Can-Stack Linear Actuators

Can-stack stepper motor linear actuators are small but can be used in many different applications. Some of those applications include:

- Medical Diagnostic Equipment

- Medical Pumps

- Printers

- Copiers

- Military Equipment

- Antenna Positioning

26 MM Can Stack Stepper Motor Linear Actuators

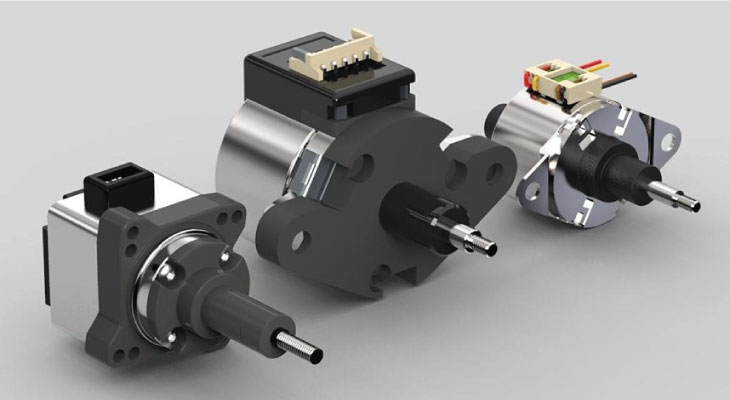

Can-stack linear actuators from Helix Linear Technologies leverage permanent magnets and stepper motor operation to convert rotary motion into linear motion in applications requiring a small footprint and high torque-to-size ratios. Our can-stack linear actuators use neodymium magnets and incorporate tight tolerances to minimize air gaps for improved performance over traditional can-stack linear actuators. Available in captive, non-captive, and external configurations, typical applications include medical equipment, laboratory instrumentation, and printing equipment.

Download our 26 mm Can Stack Stepper Motor Linear Actuator product guide HERE, or speak to one of our application engineers today.