Acme Threaded Rod 101: Effectiveness and Efficiency in Practice

Prerequisite for Acme Threaded Rod 101: Are Lead Screws Right For You?

Thread Types

The acme thread form, established over 100 years ago, replaced square thread screws with straight-sided flanks and was challenging to manufacture.

There are Three Main Classes of Acme Thread Forms

1. General Purpose (G)2. Centralizing (C)

3. Stub Acme

The General Purpose and Centralizing thread forms have a nominal depth of thread of 0.50 × pitch and have a 29° included thread angle. Trapezoidal thread forms have a 30° included thread angle. Precision lead screw assemblies have a 40° angle.

Compared to General Purpose Thread Forms

Centralizing threads are manufactured with tighter tolerances and reduced clearance on the primary diameter. Stub acme threads follow the same basic design but have a thread depth of less than one-half the pitch.

If an acme nut is side loaded with a radial load, a "G" class will "wedge" when the nut thread flanks come in contact with the screw thread flanks. To prevent wedging, less clearance and tighter tolerances are allowed between the primary diameter of the nut and the major diameter of the screw.

CAUTION - Although a side load will not cause a centralizing thread to wedge, the nut is not designed to operate with a side load such as a pulley, drive belt, etc.

Threaded Rod Terms

Land (Major) Diameter - The outside diameter of the screw.

Pitch Diameter - On an acme screw, this diameter is approximately halfway between the land diameter and the root diameter. It is the diameter at which the thread thickness equals the space between threads.

Root (Minor) Diameter - The diameter of the screw measured at the bottom of the thread.

Pitch - The axial distance between threads. Pitch is equal to the lead in a single start screw.

Lead - The axial distance the nut advances in one revolution of the screw. The lead is equal to the pitch times the number of starts.

PITCH x STARTS = LEAD

NOTE: Helix precision lead screw designations reference nominal diameter and lead. For example, a 250×125 screw advances 0.125" in one revolution and requires eight turns for one inch of travel. A 250×125 screw has 2 starts and a 0.062" pitch.

0.062" PITCH x TWO STARTS = 0.125" LEAD

Lead Accuracy - Lead accuracy is the difference between the actual and theoretical distances traveled based on lead. For example, A screw with a 0.5-inch lead and 0.004 inches per foot lead accuracy rotated 24 times theoretically moves the nut 12 inches. (24 Revolutions × .500 inches per revolution = 12.000 inches of travel) With a lead accuracy of .0003"/inch, actual travel could be from 11.996 to 12.004 inches.

Screw Starts - The number of independent threads on the screw shaft, for example, one, two, or four.

Matched Lead - When multiple screws are used to move a load with precise synchronicity, screws of similar lead accuracy can be factory selected and supplied assets. Consult the factory for matched lead set tolerances.

Straightness - Although precision lead screws are manufactured from straight, cylindrical material, internal stresses may cause the material to bend or yield.

Straightening is recommended when ordering random lengths or cutting material without end machining. Handling or machining of screws can also cause the material to bend or yield. Before, during, and after machining, additional straightening is required. When ordering screws with machined ends, the following straightness tolerances can be expected:

Precision rolled and milled lead screws are straight within 0.010 inch/foot and will not exceed 0.030 inches in any 6-foot section when shipped from the factory. Precision ground lead screws are straight within 0.001 inch/foot when shipped from the factory. If tighter straightness tolerances are required, contact Helix customer service.

Life - Precision lead screws are manufactured from high-quality materials with excellent dynamic properties. A specific life cannot be predicted because of the variable effects of friction, lubrication, and cleanliness. Proper lubrication, regular maintenance, and operation within specified limits will extend the life of lead screws.

Backdriving - Normally, lead screws convert rotary motion into linear motion. Backdriving results from the load pushing axially on the screw or nut to create rotary motion. Generally, a nut with efficiency greater than 50% will tend to backdrive. If a self-locking assembly is required, select a nut with an efficiency below 35%.

CAUTION - Vibration can cause any lead screw assembly to creep or backdrive. When using lead screws, applications should be analyzed to determine the necessity of a break, primarily when the possibility of injury may occur.

Efficiency - The efficiency of precision lead screw assemblies ranges from 15% to 85%. These efficiencies depend on acme threaded rod nut material, lubrication, lead and thread form. The efficiencies for each assembly are listed on the following pages.

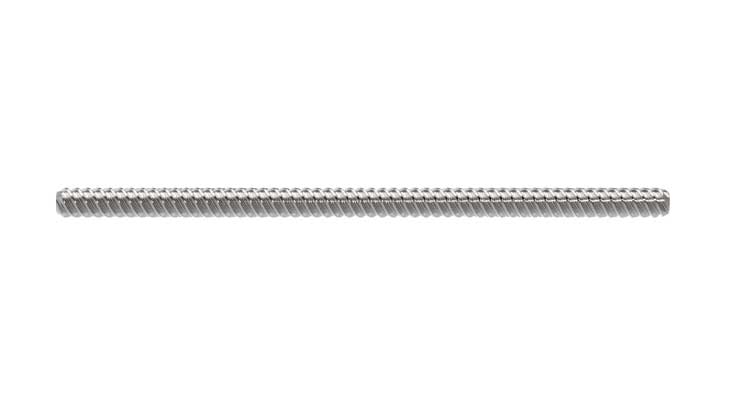

Acme Threaded Rods from Helix Linear Technologies

Our Acme threaded rods start in long lengths to be shipped to you as-is or cut and machined to your specifications.

End-machining options include bearing journals, keyways, locknut threads, flats, snap ring grooves, or any custom modifications you need. Adding machined ends to your Acme threaded rod ensures proper support and drive of the acme screw in various setups.

Standard ends are available if you need flexibility in the assembly support and drive. Do you want to do your end machining? We also supply cut-to-length Acme threaded rods so that you can add your machining for prototyping purposes.

Helix Linear Acme threaded rods are in stock and range from ¼" diameter to 2" diameter with multiple pitches and lead options.

Learn more about Acme threaded rods and lead screws here: https://hubs.li/H0Rk85G0

We'd love to hear from you!

What else would you like to know about threaded rods or any other Helix product? Let us know.