Selecting the Optimal Linear Slides for Guidance and Positioning

Achieving precise guidance and positioning through linear motion control has become a standard requirement in today's manufacturing environments. Virtually all manufacturing processes utilize some linear motion control, for which linear slides offer a simple, flexible, and cost-effective solution.

However, selecting the optimal linear slides system for your particular manufacturing application can sometimes be a confusing proposition. Both the linear motion control requirements of an application and the possible linear slide configuration possibilities vary so widely. Understanding the nuances of your application and how they dictate linear motion control parameters is critical to selecting the right linear slide for your needs. First, we must define what the term "linear slide" means.

What is a Linear Slide?

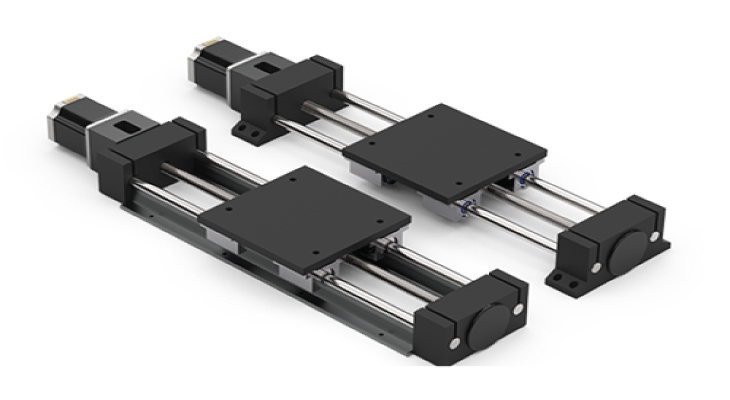

A linear slide assembly is a "system"—rather than a "component"—that controls the movement of an object by transferring power and managing friction. The linear slide system provides the interface between stationary and moving parts, precisely guiding and positioning machine components. Linear slide systems can consist of a drive element, typically a lead screw or ball screw, and guidance components like a profile rail, round rail, or a friction bearing.

Generally speaking, a linear slide based on ball screws is more precise and can carry larger loads but is more expensive than those utilizing lead screws. As Acme lead screw development continues to advance, linear slides using lead screws can deliver precise positioning,

Furthermore, by matching, configuring, and optimizing the components used in linear slides, you can achieve better overall system performance. When slide systems are used as sub-assemblies, set-up and alignment time are reduced, and linear slides are easier to specify and order. Also, there is excellent reliability and accuracy at a more affordable price.

Acme screw-driven linear slide systems include:

- Motor

- Guidance

- Bearing Support

- Lead Screw

- Carriage Plate

Many other options are available for linear slide systems, including different screw styles and leads, protective boots, unique motor mounts, and custom carriage plate machining.

Choosing the Optimal Linear Slide System

With so many variables at play, how do you go about optimizing a linear slide system for your particular application? The requirements of your applications influence linear slide system configuration and optimization. You first must fully understand these performance characteristics:

- Load – What are the weight, force, and orientation of your load?

- Orientation – How will your linear slide be positioned—horizontally, vertically, or inverted?

- Speed – How fast must the linear slide move, or how short is each cycle time? Will the system's speed be constant, or will it vary? Are acceleration or deceleration concerns?

- Travel – How far must the load be moved? Will the range of motion be along a single axis or multiple? Does your application require an emergency stop?

- Accuracy – How accurate does positioning need to be? Is repeatability important?

- Operating Conditions – In what type of environment will your linear slide operate? Is exposure to contaminants, high/low temperatures, dirt, dust, or liquids a concern? Does the system need to work in a clean room-type, contaminant-free environment?

- Life Cycle – How will the linear slide's duty cycle affect performance? What is the number of motions or strokes required? How long must the system last?

- Noise - Is there a specific amount of noise that is acceptable?

- Lubrication - Will your application allow the use of grease or a dry lubricant like PTFE (Teflon) required?

All of these operating parameters—and the interplay among them—will dictate your application's optimal linear slide system.

Manufacturing Applications for Linear Slides

Manufacturing applications and environments that are well suited for a lead screw-driven linear slide include:

- Product packaging

- Electronics Manufacturing

- Food Processing

- Component Assembly

- Material Handling

- Converting Processes

- Container Manufacturing

- Medical Equipment

- Textile Industry

- Automated Test Equipment

Use Linear Slide Systems for Efficient, Cost-Effective Manufacturing Performance

Linear slide systems that utilize lead screws can provide the precise guidance and positioning required by today's manufacturing processes. Thoroughly understanding the parameters of your linear motion application and working with a partner with experience in configuring application-specific linear slide solutions can help you optimize a linear slide system for your unique needs.

To learn more about how Helix Linear Technologies can help you design an ideal linear slide system for your manufacturing process, contact us today!