Follower Nut Assemblies: Identifying Wear

Identifying Wear with Follower Nut Assemblies

With any frictional product, wear is inevitable. Whether the products are jacks or acme screws, at some point the thread will no longer support the load and will fail. This can lead to personal injury or equipment damage that will create significant value loss. Due to the function of the acme thread engagement, it is not possible to see the nut threads wearing. Fortunately, wear-indicator nuts, or follower-nut assemblies, can help end users identify when such wear is approaching the point of failure with the use of sensors, gauges or visual indication, depending on the application.

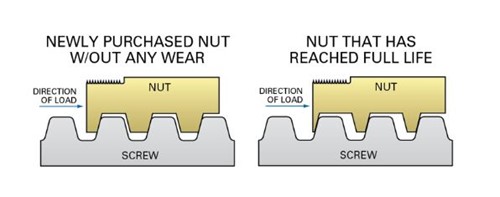

Wear-indicator nuts are relatively simple devices. As the acme thread wears, the thread gets thinner, the integrity of the nut can be lost and the acme nut can no longer support the load and eventually will lead to the thread stripping out of the nut. Because of this, the full life of the nut is considered to be when the thread is halfway through its tooth thickness, or a quarter of the pitch of the screw. At this point, the nut will no longer have the integrity to support the load to the rating of the nut.

While designers anticipate wear and when the thread has reached its full life, there is an underlying challenge of knowing exactly when this is happening, because it is happening inside the nut. However, it is possible to measure the wear because it is directly related to the lash of the nut, or the linear displacement of the nut in relation to the screw. Operators or maintenance staff can displace the nut back and forth and physically measure how thick that tooth is by measuring that displacement, or lash.

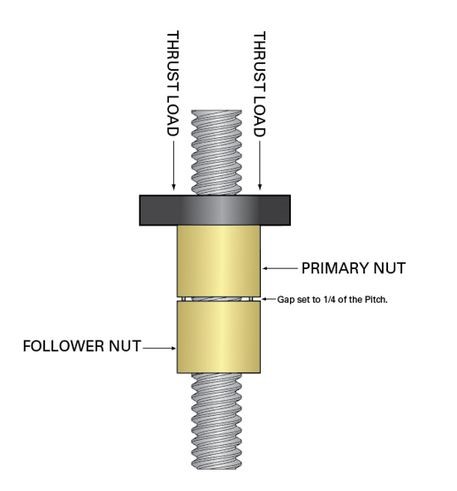

The use of a wear-indicator nut makes this task a whole lot easier. A wear-indicator nut is actually two nuts assembled together, a primary nut and a follower nut. The primary nut and follower nut is typically made out of a bronze material that is softer than steel. The follower nut is pinned to the primary nut and follows along. As you apply Newton's Law of universal gravitation, the primary nut will fall with respect to the second following nut as the thread gets thinner due to normal wear. The second nut is not carrying any load but is only pinned to the primary nut to follow along.

Since both nuts are resting on the flank of the thread, this gives a known position for both nuts. Now, you can measure the gap or physical distance between the primary and follower nuts and have an understanding of the true thickness of the acme nut thread. Therefore, if there is one nut resting on the flank of the thread and a second nut right below it resting on its flank, it is possible to measure the distance. If one nut carries load and the other does not, only one of the two nuts will show wear. As the thread of the primary nut gets thinner, one nut will fall with respect to the other. As the gap gets smaller, maintenance personnel can measure how much wear has occurred on this thread. If a designer sets the gap to be a quarter of the pitch, they will know the thread is halfway through its tooth thickness when the gap is closed. For example, a 1-inch 4 acme screw has a pitch of a quarter of an inch. This gap would then be set to a 1/16-inch, and as the nut wears and the gap closes, maintenance personnel can see that the thread has worn through half the tooth thickness.

Types of Wear-Indicator Nuts

Both the primary and follower nuts are typically made out of bronze. Some designers request the follower nut to be made of steel. When the follower nut is made from steel and the gap is closed between the two nuts from wear and the load begins to transfer to the steel nut, a loud noise can be heard and used as an audible indicator.

Measuring the Gap

Although the steel-on-steel noise from a steel following nut can be an indicator, there are other ways to measure the gap for both steel and bronze wear-indicator nuts.

One very basic way to determine the wear is by visual observation at the gap between the nuts. Visually observing when the gap closes will give a positive indication of the amount of wear that has occurred and indicate the need to replace. This method is open to error, because it is subjective.

A feeler gauge, or go-no gauge, is the preferred way to indicate when gap closure occurs. These gauges provide a simple, pass/fail-type inspection tool that is easy to interpret on a production floor. The gap is set by the factory, and with the use of a feeler gauge, you have a physical, absolute indicator that most maintenance personal will be familiar with.

When the accessibility of the travel nut is restricted, systems can be designed with an electronic proximity sensor to indicate the closure of the gap between the primary and follower nuts. These can be specifically designed for custom solutions to serve a specific application. While electronic sensors have their benefits, they can sometimes be accidentally turned off, which can lead to damage if the wear on the nut isn’t detected until it’s too late.

Design Considerations of Wear-Indicator Nuts

Design lift platform systems with wear-indicator nuts promote a safer working environment and mitigate risk for material loss and breakdown with a minimal cost.

For wear-indicator nuts, the load must be in a vertical plane so gravity can pull the load in a downward direction. A wear-indicator nut can be used whether the primary nut is rotating or if the screw is rotating. If an operator is unable to physically check the nut, a sensor or remote-controlled system needs to be installed.

Some manufactures refer to wear-indicator nuts as "Safety Nuts." Users should treat this term with caution. The use of the word “safety†implies some form of mechanical prevention of failure. In other words, as the acme nut thread is approaching the point of failure due to wear, a “safety nut†would actively prevent this failure. In reality, wear-indicator nuts indicate the amount of wear that has occurred on the primary nut. Thus, allowing the primary nut to be replaced prior to failure when it is no longer able to support the load. If a wear-indicator nut is allowed to continue to be in service after indication that the primary nut as exceeded its full life, acme nut failure can occur. Therefore, wear-indicator nuts still require some form of intervention once the primary nut has reached its full life.

Benefits of Wear-Indicator Nuts

For applications involving any sort of lift platforms, losing the integrity of the nut can result in serious injury if left unchecked. This puts a heavy responsibility on maintenance personnel whose job is to inspect the integrity of the nut. With a wear-indicator nut, maintenance personnel can observe the life of the nut and not have to physically measure it by lifting the nut and lash of the nut, which requires them to completely dismount the load. Using a wear-indicator nut has very little impact on costs. Nuts are relatively inexpensive compared to the costs of equipment or physical damage if a failure were to occur.

Wear-indicator nuts can be added in retrofit in some applications and are ideal for new system designs. Overall, wear-indicator nuts are designed so that operators and maintenance staff can detect wear before the nut has potential to cause damage or injury from stripping. Therefore, it is very important to train operators and maintenance staff how to use and take care of wear-indicator nuts so that these incidents do not occur.